Plan the integration and coordination of energy systems, including electricity, gas, and thermal networks.

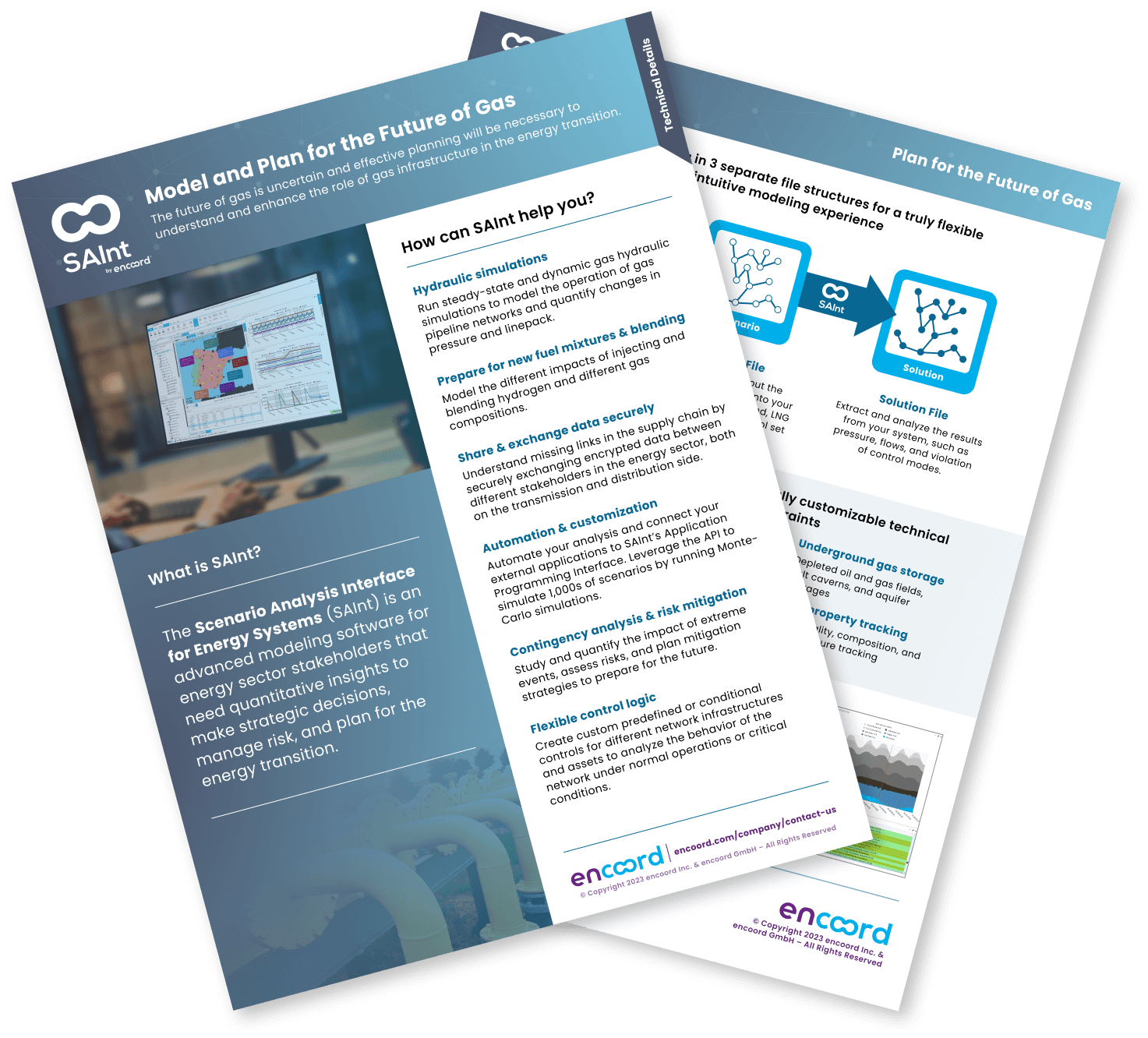

Plan for the Future of Gas

The future of gas is uncertain and effective planning will be necessary to understand and enhance the role of gas infrastructure in the energy transition.

The challenges the industry is facing

Gas diversity

Gas supply qualities and compositions will change and challenge current modeling and planning practices.

Operational and strategic planning should be coordinated

Strategic planning without consideration of operational realities increases costs and risks. Operational planning without strategic guidance slows growth.

The future role of gas is uncertain and hard to plan for

What is the most efficient, effective, and economic path to decarbonization?

Time and cost

Multiple planning platforms and data sources increase cost and time while reducing trust in the decision process.

How encoord provides the solution

The Scenario Analysis Interface for Energy Systems (SAInt) is a software platform designed to model integrated energy networks and markets.

Model gas pipeline transmission and distribution networks.

encoord provides advisory, training, data, and support services to help you implement SAInt and better plan for the energy future.

Want the technical flyer?

Check out our flyer on gas planning to learn more.

See how to plan for...

Electricity

New technologies, requirements, and demands in electricity are changing the world. A better planning solution is needed.

Hydrogen Integration

Alternative fuels cause their own mix of challenges. How do you plan for greener fuels?

Renewable and Storage Integration

Renewable generation and storage technologies can cause as many problems as they solve. Careful scenario planning is required to quantify and minimize risk.

Thermal Networks

Heating and cooling demands are large and represent potential sources of flexibility. How do you plan the future of thermal networks?